The Objective

Plan, coordinate and check Mechanical and Electrical works using BIM to deliver the best outcomes in the construction of a midrise mix development condominium

The Challenges

As senior M&E engineer on the operations team, Sunta’s role is multifaceted, from dealing with design and technical queries in weekly coordination meetings to material procurement and ensuring smooth execution at the project site.

Before BIM, Sunta finds that his daily schedule was consumed by lengthy discussions, facilitating works coordination and resolving disputes between different parties, on-site and offices. These are common pain points in construction where teams are often segregated by work disciplines, each with independent work programmes, drawings and specifications.

To illustrate, at peak project stage, Sunta might find himself in an average of 3-4 meetings a day, coordinating converging disciplines such as Civil and Structural, Architectural works, etc, between suppliers, subcontractors, consultants and so on.

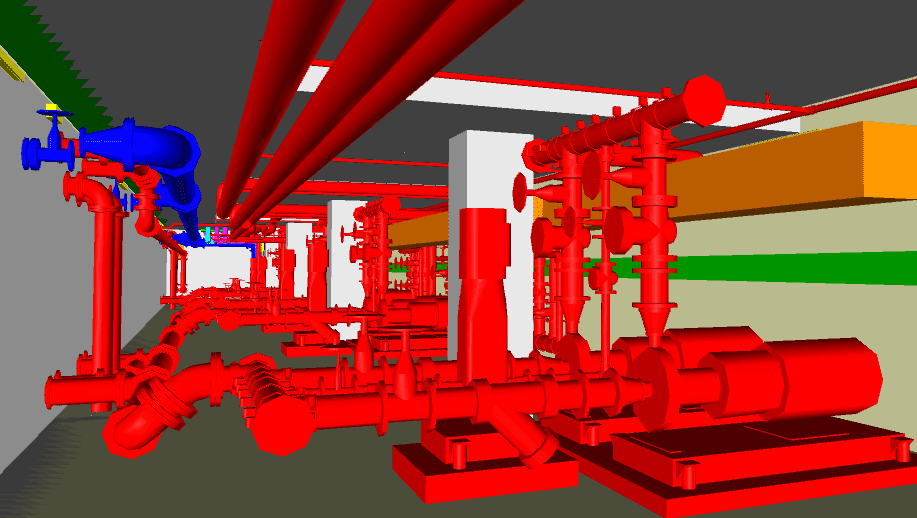

Although not immediately obvious, this maze of cables and piping overhead consists of elements for fire emergencies, swimming pool piping, electrical cabling, lighting and so on. These had to be carefully coordinated and tailored to fit the building’s Architectural requirements such as headroom allocations.

The Outcome

3D visualisation

The starkest advantage BIM offers is the ability to grant project visibility to entire teams and tangibly demonstrate how different works interrelate. This also grants clarity in communicating and understanding the roles and contributions of each party to the project’s success. Stakeholders can immediately see from the design models compared against actual site progress, crucial information such as potential clashes, legal, or safety concerns and more.

Detailed BIM visualisation of the fire pump room.

Time saving

Sunta notes that using the 3D BIM models had smoothened discussions, reporting tasks and overall management of the supply chain significantly, freeing the team to focus on high-value tasks. It also allows the operations team to be more hands-on with site progress on a day-to-day basis, resulting in better workmanship and quality performance.

Teachable Points

Start with the why, rather than how

Proactive BIM advocates like Sunta and team makes a strong case for BIM adoption by demonstrating its real-life tangible value to stakeholders. While it’s important to offer sufficient resources and training to help staff overcome their reservations with new technology, the best way to gain buy-in is by appealing to the intrinsic rewards of wielding such a powerful tool.

Sunta shared how a particular supplier was impressed by the 3D visualisation of the building’s Main Switch Board (MSB) using BIM. Typically, 2D drawings do not capture granular details like plinth, overhead cable, bust duct, and transformer positions.

The more the merrier

The benefits of BIM compound with its level of adoption across the board. Sunta hopes to see more integration and utilisation of BIM systems throughout a project’s lifecycle, as well as see its capabilities expanded into other areas such as quantity surveying, and future maintenance & asset management. This would greatly centralise and democratise project information and close the gaps in operations due to humanly shortcomings.