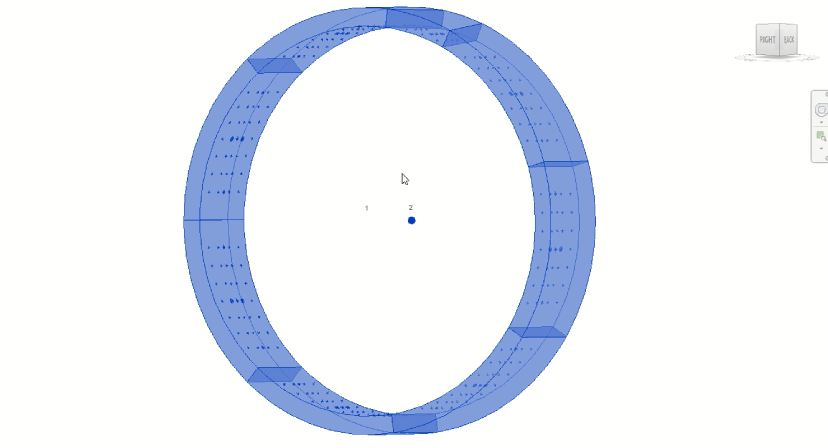

In short: Using computational BIM via Autodesk Revit + Dynamo, we save a lot of time in obtaining the coordinates of the centre of the tunnels taking into account all rotational movements of the tunnel, crucial for alignment and the placement of service brackets on tunnel segments.

The Complexities of Tunneling for Large Infrastructure Projects

Tunneling segment design has always been complicated and filled with risk. One of our projects that relies on our tunneling expertise is the RM1.77bil CR209 project in Singapore that aims to benefit 40,000 households living on Sunset Way and along West Coast Road.

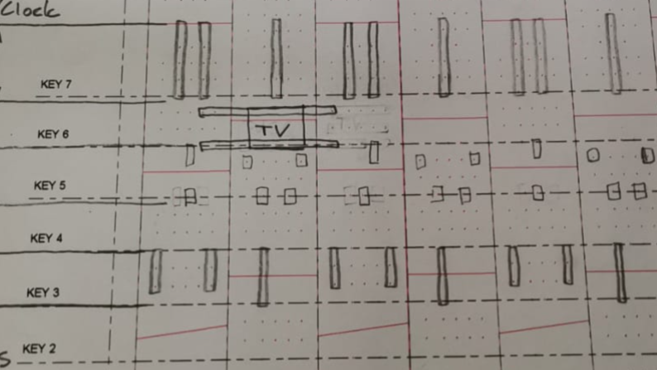

An important aspect of tunnel engineering is the service bracket coordination which relies heavily on manual calculations and 2D modeling. This method takes up a lot of time and manpower, particularly when dealing with tunnels that have varying elevations.

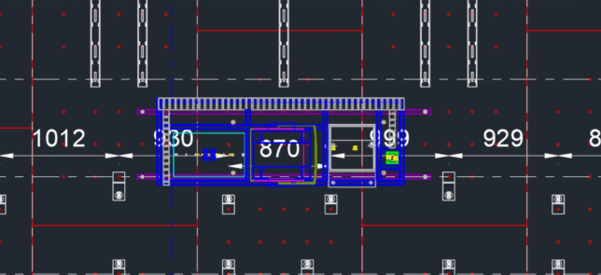

Traditionally, tunnel modeling relied on 2D AutoCAD plans, a method bogged down with time-consuming processes and a plethora of ways for potential errors to occur. These discrepancies may led to significant deviations in tunnel alignment.

Using Technology to Replace Traditional Methods of Calculations and Modelling

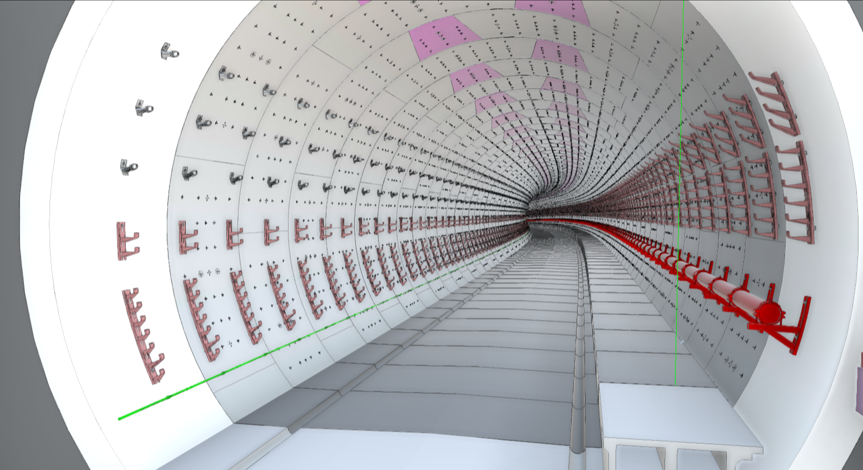

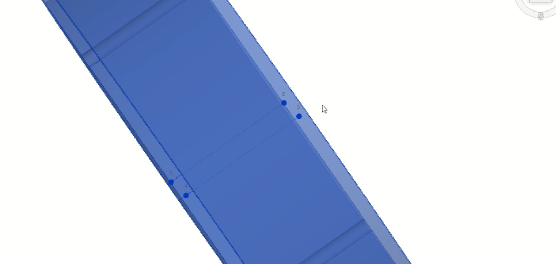

Our team in Gamuda Singapore, led by Thinagar Ramalingam, has employed an ingenious way of using computational BIM to design the dimple holes that are present in tunnel segments. These dimples are used to coordinate the service brackets, which will be drilled and mounted only at the dimple hole locations.

Drilling is not permitted outside these dimple holes to prevent damage to the segment rebar and to preserve the waterproof integrity of the tunnel segments.

Autodesk Revit, which has revolutionized this process, drastically reduces potential errors from manual calculation. Combined with Dynamo, a graphical programming interface that customizes building information workflows, Gamuda teams can now generate detailed 3D models that integrate live data from the dig site for improved precision.

Basically, we are using programming to automate the tunnel centre coordinates and to run the tunnel segments in to its aligment using Dynamo scripts.

Ramalingam Thinagar – BIM Coordinator (GAMUDA Singapore)

Dynamo scripts can derive tunnel center coordinates and adjust for elevation data, ensuring precise alignment and reducing human error. These data are then verified by M&E managers and tunnel engineers on site.

By using Dynamo to automate tunnel center coordinates and dynamic data inputs eliminates hours of manual calculations and reduces errors, particularly in tunnels with varying elevations. This automation also streamlines the ordering of brackets, improving overall project efficiency.

Looking Ahead: Better Tunneling Methods for The Industry and the Community

Digital engineering and advanced computational tools have a role in enhancing the precision and efficiency of tunnel construction projects, and the steps many projects can take to further improve the industry at large.

The adoption of more technologies available today in tunnel construction is part of the long road map for Gamuda’s construction projects. As the industry continues to evolve, such technologies will play a crucial role in driving efficiency and precision in construction projects.